Fully Automatic Servo System 1-Cavity Bottle Blowing Machine

- Category:Blow Molding Machine

The 20L fully automatic bottle blowing machine is suitable for the domestic oil bottle industry market. Currently, well-known industries such as COFCO Longda Fulinmen have our company's 20L fully automatic bottle blowing equipment. Secondly, the bottled water industry also needs 20L automatic machine equipment!

- Inquiry Email

Product basic introduction

| Equipment type | Automatic |

| Bottle Volume(liter) | 20 |

| Output(bph) | 400 |

| product | Water bottle,Containing cylinder,Cosmetic bottles,Cantonese Food Bottle,Milk and dairy products,Beer,Water and CSD |

The advantages of the 20L fully automatic bottle blowing machine are:

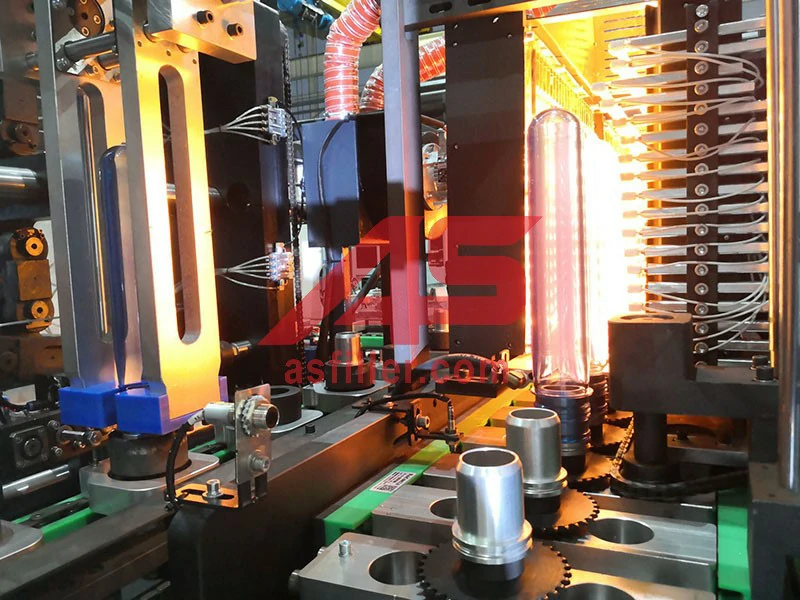

1. Heating the SCR voltage stabilizing device, the temperature will not fluctuate and affect the bottle blowing.

2. After the bottle preform is heated, it is transferred to the bottle blowing section. There is an internal heating system to fully heat the inner wall of the bottle preform, making the bottle more beautiful and reducing the scrap rate.

3. Strong compatibility, compatible with 10-30L beer barrels.

4. The machine can be equipped with an optional gas recovery device

5. Oven drive servo, main drive servo, mold closing servo and stretching servo are optional.

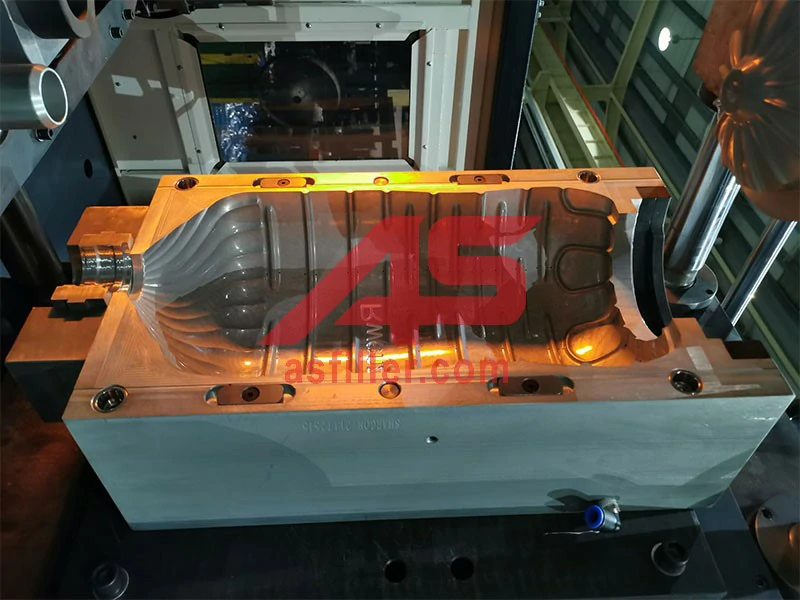

6. The mold material is 7075AL, which is lightweight and has fast heat dissipation.

7. Fast, can blow 500-600 bottles per hour

Technical data

| Number of cavity | 1 cav | Output | 200 pcs/hr |

| MAX. BOTTLE VOLUME | 20.0L | NECK MAX DIA. | 95 mm |

| BODY MAX. DIA | 300mm | HEIGHT | 500mm |

| HEATING LAMPS | 65pcs | MAX. HEATING POWER | 85kw |

| INSTALLED POWER | 95kw | ACTUAL POWER | 48kw |

| WORKING PRESSURE | 8 bar | BLOWING PRESSURE | 35 bar |

| HP POWER | 4000-5000 Ltr/min | WORKING POWER | 5-6 kg/c㎡ |

| TEMP | 10℃ | COMSUMING | 8000kcal/hr |

| FLOW | 88Ltr/min | DIMENSION | 5.x2.5x2.1(m) |

| WEIGHT | 7000KG |

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:008613862109056

Whatsapp:008613862109056

Email:ella@asfiller.com

Add:Xinyi City, Jiangsu, China