Carbonated soft drinks lines Introduction

Carbonated soft drinks lines Introduction

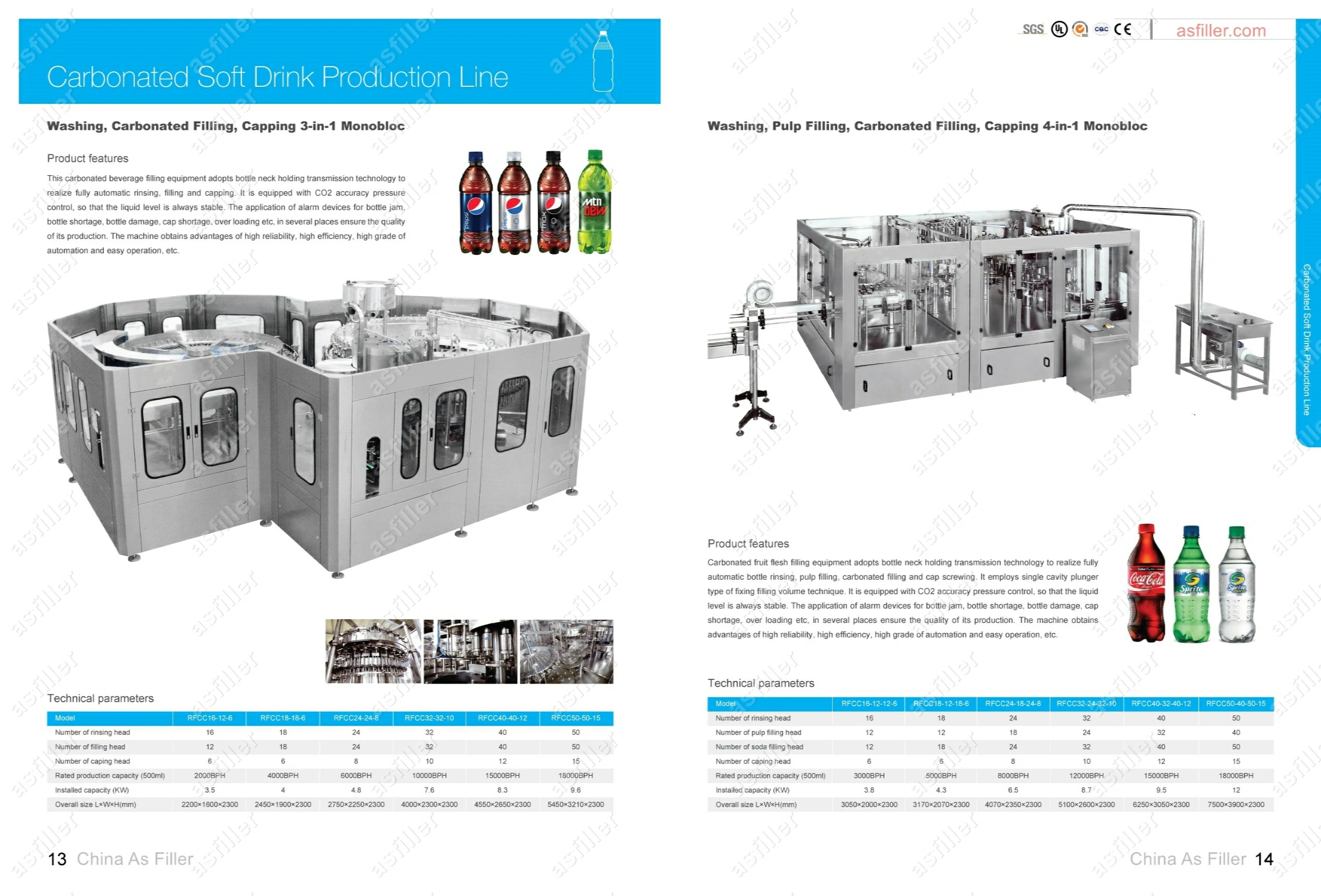

Coke, Sprite, soda water, salted soda water, carbonated drinks, cocktails, flavored water. There are many kinds of carbonated drinks that are constantly changing, and new trends, varieties and packaging are constantly emerging. For CSD filling machine, how to raise the filling temperature as much as possible to reduce energy consumption, how to reduce the generation of bubbles, how to ensure the liquid level accuracy, how to prevent no residue in the bottle neck finish, how to ensure the CO2 content? It is not a simple task to handle these problems skillfully. For CSD filling machine, how to raise the filling temperature as much as possible to reduce energy consumption, how to reduce the generation of bubbles, how to ensure the liquid level accuracy, how to prevent no residue in the bottle neck finish, how to ensure the CO2 content? It is not a simple task to handle these problems skillfully. However, no matter what products you produce, As Filler can help you achieve your goals with the best technology. At the same time, as required, As Filler can also realize multi-purpose of one machine, that is, the same equipment can meet the filling needs of water, hot, CSD and other products!

Equipment advantages and features

However, no matter what product you produce, As Filler can help you achieve your goals with optimal technology solutions. If needed, our machinery can also be multi-purpose, with the ability to meet the filling needs of water, hot beverages, gas and other products.

● The CSD filling temperature of flowmeter can be above 15 degrees.

● The filling without purging is possible for high CO2 utilization rate.

● Higher air content.

● Measured in terms of filling capacity with high accuracy.

● High speed, up to 60000BPH (500ml).