Cans Production Filling Line

We are a comprehensive professional supplier of Cans Production Filling Line integrating R&D, manufacturing and sales. We can provide turnkey projects and have professional after-sales service engineers. Currently, the equipment is exported to more than 30 regions and countries in domestic and foreign markets.

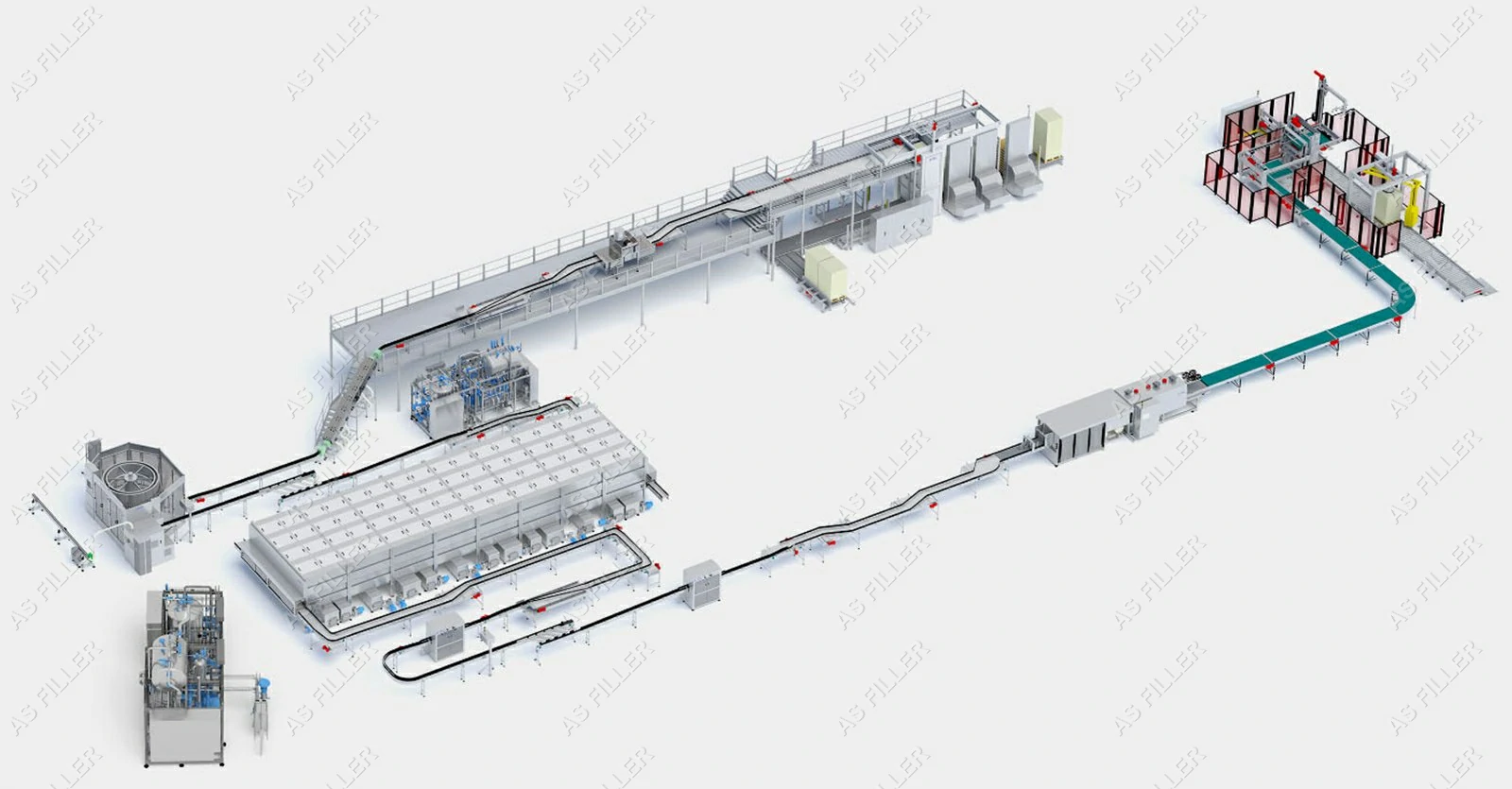

The Cans Filling Production Line equipment we provide includes the

1.Water Treatment System,

2.Beverage processing system,

3.Tunnel Pasteurizer,

4.CIP System,

5.Filling and Capping Machine,

6.Labeling Machine,

7.Packaging Machine,

8.Conveyor Machine,

and other necessary equipment.These devices are widely applied in the production lines for canned fruit juice, canned beverages, and canned beer.

You can obtain the price for individual equipment as well as solutions for the entire production line.

Get Quotes And Specifications

Empty can depalletizer is mainly used in unloading empty aluminum cans operations. It pushes the top-down of pallet layer by layer to the conveyor, and then sends cans to the can rinser. This machine replaces the manual way of putting cans in order and saves manpower.

The gas line is popular among young people. Compared with the waterline, it is relatively complex in technology. The beverage mixing system – refrigeration unit – carbon dioxide mixing system and CIP cleaning system of the production line need to be added.

The carbonated beverage production line can be divided into carbonated beverages such as Coca Cola, aerated soda water and natural aerated water according to different tastes and processes.

Our Advantages

1. Plant design is the first link of the whole project. The perfect design can improve the production efficiency of the production line. We can provide customers with perfect design scheme according to the actual situation.

2. The choice of equipment directly determines the quality of products. We can provide a variety of high-quality equipment according to customers' technological requirements.

3. Good engineers can improve work efficiency. We can send experienced engineers to the customer's factory for installation and debugging, train employees, and escort the normal operation of the production line.