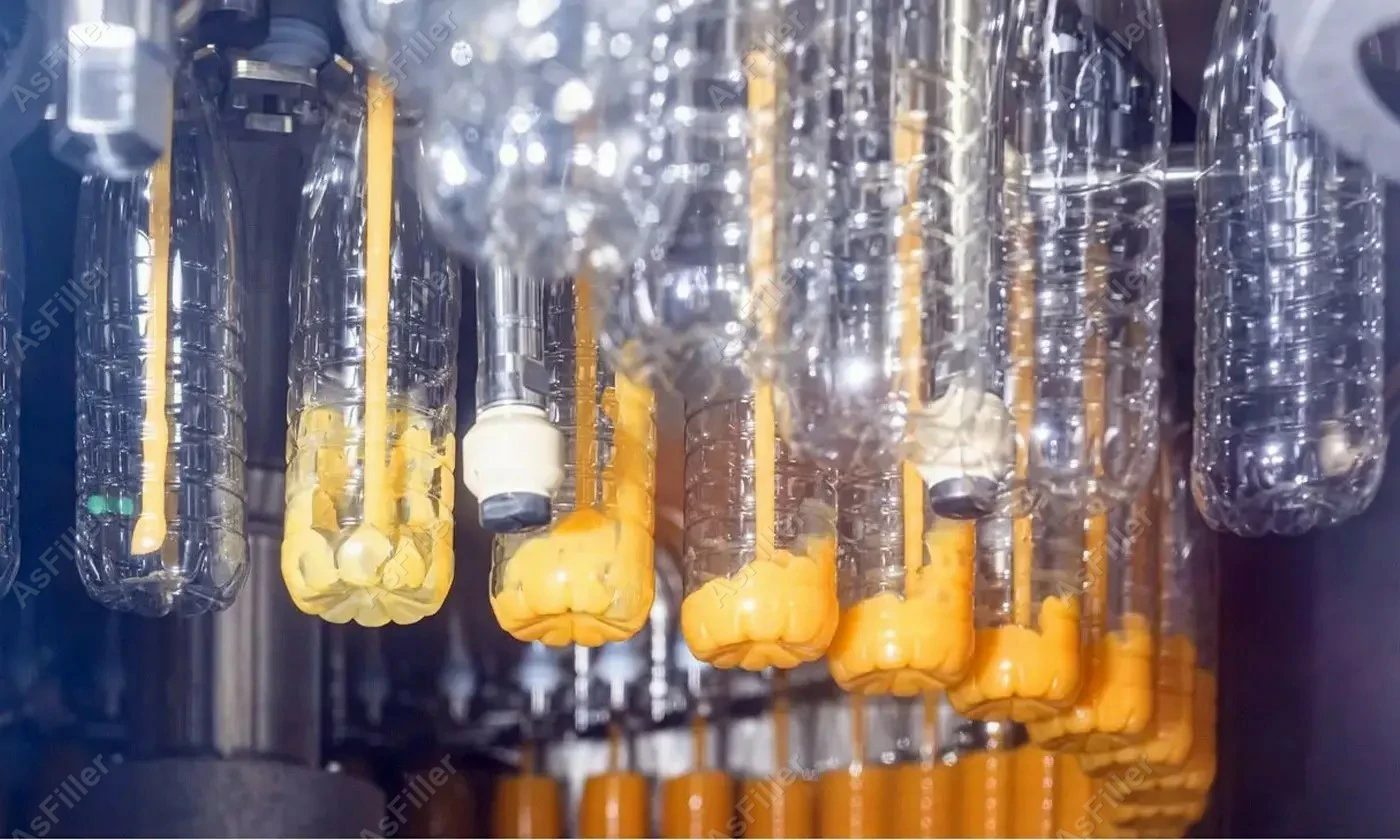

Fully Automatic Beverage Filling Machine

- Category:Filling Machine

- The automatic beverage filling machine is widely used in the production lines of carbonated drinks, mineral water, fruit juice, tea, and beer. It is an integrated equipment that combines rinsing, filling, and capping. Capacity : 2000-30000 Bottles/Hour(customized). Price : Factory Direct Sales Price. Warranty : 24 Months. Other : Customizable. Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

- Inquiry Email

Brief Introduction

Fully Automatic Liquid Beverage Filling Machine is 3-in-1 filling machine which combines rinsing, filling capping in one machine. The equipment is innovated and developed based on the introduction, digestion and absorption of foreign advanced technology and according to the gas-bearing beverage filling process requirements,. It is mainly used for gas flushing, filling and capping plastic pre-threaded cap soft drinks, cola, sparkling wine, mineral water, beverages etc. The machine has reasonable structure, safe, reliable, easy to maintain and it is the ideal equipment for beverage filling factory.

We is a professional manufacturer of Beverage Filling Machine. We offer factory-direct prices and can customize products to meet your needs. Please feel free to contact us at any time to request a quotation and product specifications.

ales Scope : global sales.

Showroom Location : China, Bangladesh, Algeria, Colombia, Albania.

Product Parameters

Model | DXGF24-24-8 | DXGF32-32-8 | DXGF40-40-10 | DXGF50-50-12 | DXGF60-60-15 |

Capacity (for 500ml) | 8,000BPH | 12,000BPH | 15,000BPH | 18,000BPH | 21,000BPH |

Bottle diameter | 50~110mm | ||||

Bottle height | 160~310mm | ||||

Air source pressure | 0.7MPa | ||||

Main motor power | 3.0KW | 4.0KW | 7.5KW | 7.5KW | 11KW |

Dimension | 2800*2230*2700 | 3550*2650*2700 | 4360*3300*2700 | 4720*3545*2700 | 5770*5288*2700 |

Product Features

1.By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

2.The Automatic Beverage Filling Machine parts directly contacted with media are all adopted with food stage stainless steel without dead angle, so they can be cleaned easily.

3.Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

4.Periodical gas exhaust and fast and slow snifting prevent product foaming.

5.Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

6.Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, ensure filling accuracy.

7.Simple internal filling valve chamber without springs ensure thorough cleaning & sanitation. Automatic CIP cups are highly efficient.

8.The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

9.The Fully Automatic Beverage Filling Machine is adopted spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel. And to adjust the input height is not necessary for exchanging model of bottle.

10.All control is advanced touch-screen operation and realize people-computer dialogue operation.

Product Configurations

| Name | Supplier |

| Main Motor & Reducer | SEW-Germany |

| Rinsing Pump | CNP-China |

| Inverter | SIEMENS-Germany |

| PLC | SIEMENS-Germany |

| Touch Screen | SIEMENS-Germany |

| Contactor | SCHNEIDER-France |

| Hot Relay | SCHNEIDER-France |

| Air Switch | LEUZE/BANNER-Germany |

| Photoelectric Switch | BANNER-USA |

| Pneumatic Components | FESTO-Germany |

| Sliding Bearing | IGUS-Germany |

Rinsing Part

1. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

2. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall,

saving rinsing water.

3. Covering of bottle clamps and elevator are product of Igus.

Filling Part

1. Each filling valve is equipped with an air return channel independent of the liquid cylinder. The replaced air in the PET bottle does not enter the liquid cylinder during the filling process.

2. The filling valve is equipped with a cleaning cup, which can thoroughly CIP cycle clean the filling valve.

3. Adopt lifting cylinder bottle lifting mechanism, using bottle clamp technology to avoid pollution.

Capping Part

1. Adopt magnetic constant torque screw cap head, and the screw cap effect is stable and reliable.

2. The fall guide rail has the device to prevent the reversal cap from passing and pick out the reversal cap.

3. It has the bottle check-up switch to control the cap flow and stop it in case no bottle to reduce the cap quantity.

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:008613862109056

Whatsapp:008613862109056

Email:ella@asfiller.com

Add:Xinyi City, Jiangsu, China