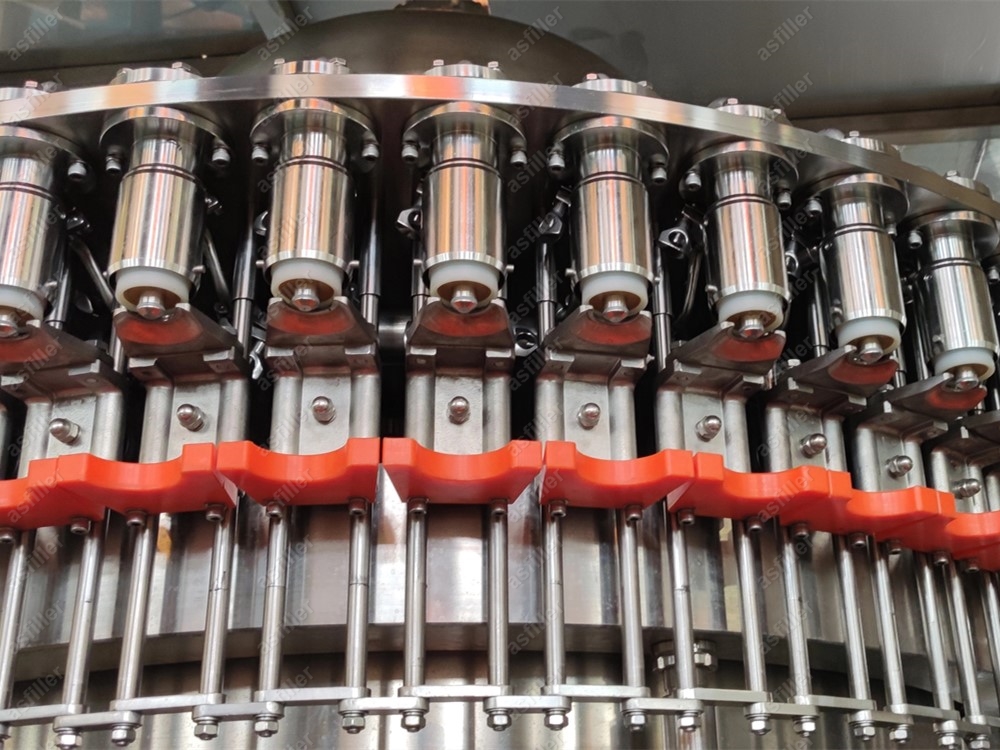

Bottle Water Filling Machine

- Category:Filling Machine

- Every day, millions of glass bottles, cans and PET containers run through a AS Filler beverage filling machine line. As a manufacturer for complete filling machine systems, AS Filler provides breweries, beverage bottlers to all over the world with single machine or complete Beverage filling machine production lines.

- Inquiry Email

As a customer looking for filling solutions, you may be interested in exploring our range of Filling products. Our Filling machines are designed to offer efficient, precise and reliable product filling across a range of industries.

Our Filling machines boast state-of-the-art technology, enabling accurate dosage control, high-speed output and minimal maintenance requirements. This means that businesses can enjoy faster and more efficient production processes, with reduced waste and greater control over their output.

In addition to their advanced features, our Filling machines are also highly customizable, allowing customers to configure their machines to meet the specific needs of their industry and products. We work closely with our customers to ensure that each machine is tailored to their requirements, whether it be in terms of capacity, speed, or type of fill.

Compared to other filling solutions on the market, our Filling machines offer exceptional value, combining cutting-edge technology with unparalleled flexibility and customization options. So why not browse our range of Filling products today and see how they could benefit your business? With our commitment to quality and customer satisfaction, you can rest assured that you are investing in a superior filling solution.

Partial Products Main Technical Parameter

| Model | Washing heads | Filling heads | Capping heads | Production Capacity | Machine Power | Weight | Overall dimension (mm) |

| CGF14-12-4 | 14 | 12 | 4 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| CGF18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| CGF24-24-8 | 24 | 24 | 8 | 8000B/H (500ml) | 5kw | 6500kg | 3100*2450*2300mm |

| CGF32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| CGF50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900 mm |

Technical data

| Filling Method |  |  |

| Mechanical Valve Filling | Flow Meter Filling | |

Applicable Bottle Type | PET/Glass | PET |

| Technical Features | ● Different length of vent tubes to control fill level ● Sanitary design ● Filling with reflux or filling without reflux ● Light weight bottle handling | ● Accurate fill level control ● Non-contact filling, more hygienic ● Automatic CIP with dummy bottles ● Optimal flow path in filling valves to ensure the complete CIP ● Flow meter selection based on water conductivity ● Faster filling speed ● More adaptable for light weight bottle ● Fast recipe change ● Easy maintenance |

| How to Choose? | ● Low capex and low operating cost | ● More hygienic filling ● Accurate filling ● Automatic CIP dummy bottles |

| Capacity | 80,000 bottles per hour | 100,000 bottles per hour |

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:008613862109056

Whatsapp:008613862109056

Email:ella@asfiller.com

Add:Xinyi City, Jiangsu, China