Blow Molding Machine

- Category:Blow Molding Machine

AS-6000 Servo System automatic bottle blower is a series of models produced by our company. This model uses advanced design concepts, excellent workmanship and high-quality well-known brand parts, which is suitable for PET with various shapes of various shapes. The bottle locking component adopts a dual crankshaft lock structure, the supporting FESTO mold lock cylinder, or the servo mechanism, which is heated quickly and runs quickly and smoothly.

- Inquiry Email

AS-6000 Servo System automatic bottle blower is a series of models produced by our company. This model uses advanced design concepts, excellent workmanship and high-quality well-known brand parts, which is suitable for PET with various shapes of various shapes. bottle.

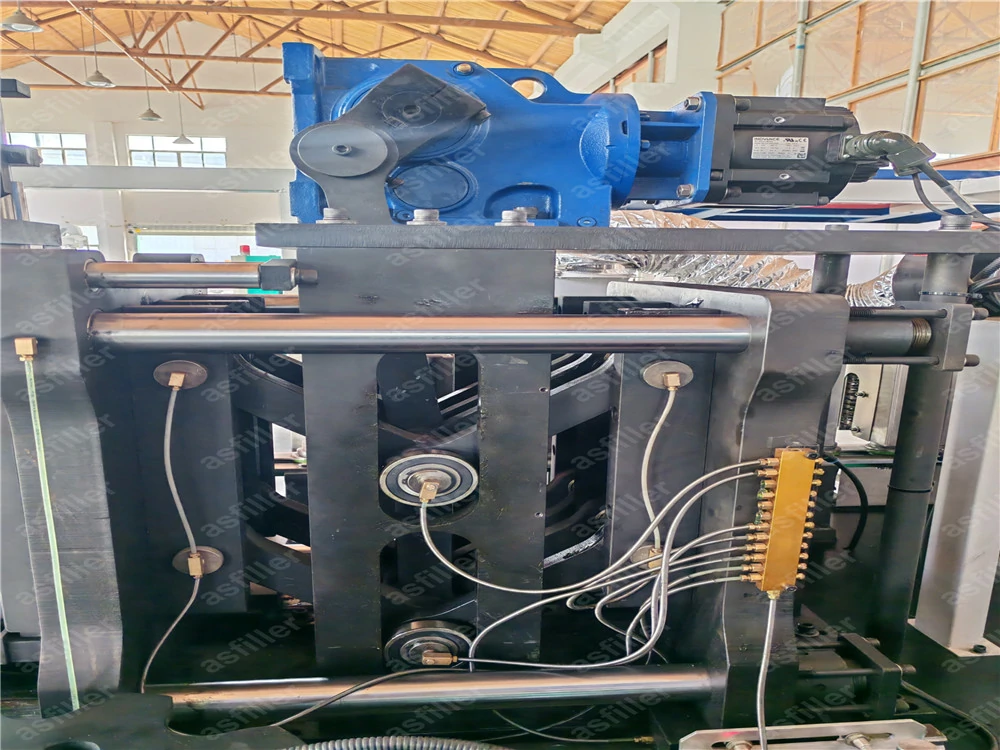

● Model locking components adopt a dual crankshaft locking structure, supporting FESTO mold lock cylinder, or servo mechanism, run fast and smooth;

● The heating part is controlled by a far -infrared oven, the pressure regulating module is controlled, and each section of the lamp tube controls the temperature independently, which is suitable for different height bottle embryos, which is uniform heating;

● The airway system is divided into high -pressure, pre -blowing, and low pressure. All pneumatic elements are native to Europe, Japan, and Taiwan.

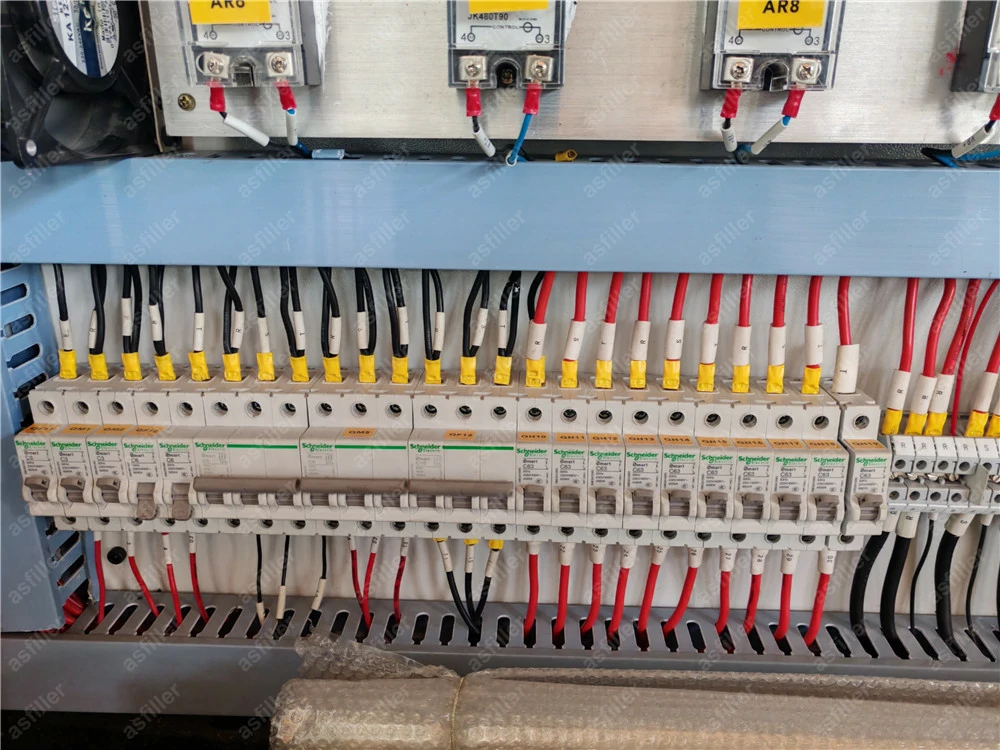

● The electronic control part is controlled by PLC, touch screen operation, humanized operation interface, easy to understand, easy to use;

● The electrical components of the whole machine adopt well -known brand parts at home and abroad to ensure the long -term stable operation of the machine;

● The running mode of the whole machine can be divided into two types: manual and fully automatic. It has a complete fault alarm and prompt function to facilitate customers to repair it by themselves;

● You can choose the servo system for stretching movements and embryos.

● The whole machine is equipped with a full -automatic bottle embryo feeder, stainless steel fighting, and you can choose a single skating or multi -slide down embryo system;

Technical data

| BottlePET | Item | Unit | Parameter |

| Max. volume | L | 0.6 | |

| Max. neck Diameter | mm | 38 | |

| Max. bottle Diameter | mm | 68 | |

| Max. Bottle height | mm | 240 | |

| Machine | Cavity no. | Cav | 6 |

| Capacity. | Bottle/H | 8000(500ml) | |

| Bottom stroke | mm | 60 | |

| Clamping force | KG | 48000 | |

| Clamping stroke | Mm | 120 | |

| Stretch stroker | Mm | 240 | |

| Heating power | Kw | 55 | |

| Installation power | Kw | 70 | |

| Power supply | 380V,50HZ,3P | ||

| Overall dimension | m | 3.6x1.93x2.03 | |

| Weight | Kg | 3500 | |

| Air compressor | Low pressure | Mpa | 0.8-1.0 |

| Low pressure consumption | L/min | 2000 | |

| High pressure | Mpa | 3.0-3.5 | |

| High pressure consumption | L/min | 3000-3500 | |

| Water chiller | Pressure | Mpa | 0.3-0.5 |

| Temperature | ℃ | 10-15 | |

| Water flow | L/min | 60-90 |

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:008613862109056

Whatsapp:008613862109056

Email:ella@asfiller.com

Add:Xinyi City, Jiangsu, China